Projects

Assorted Projects

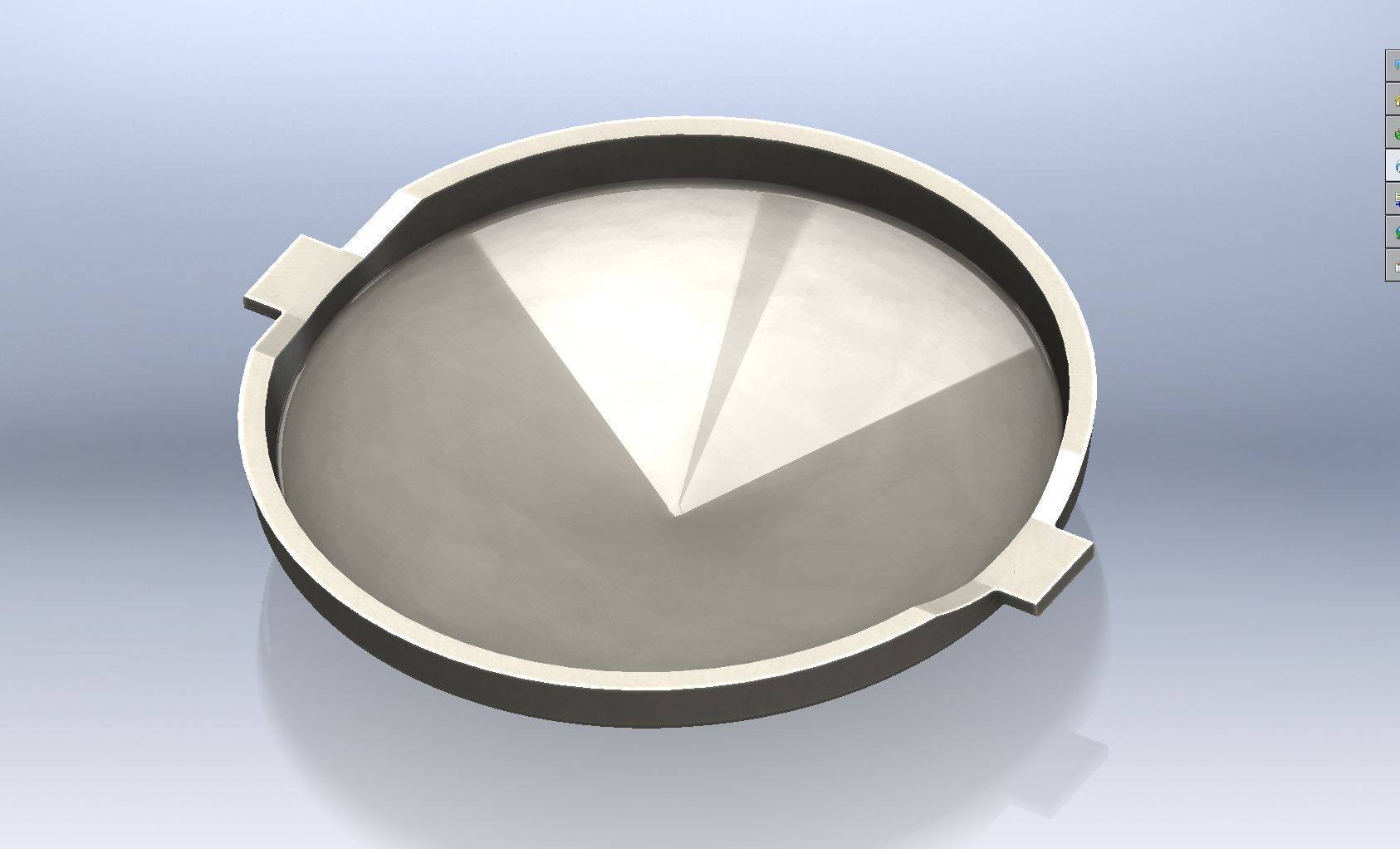

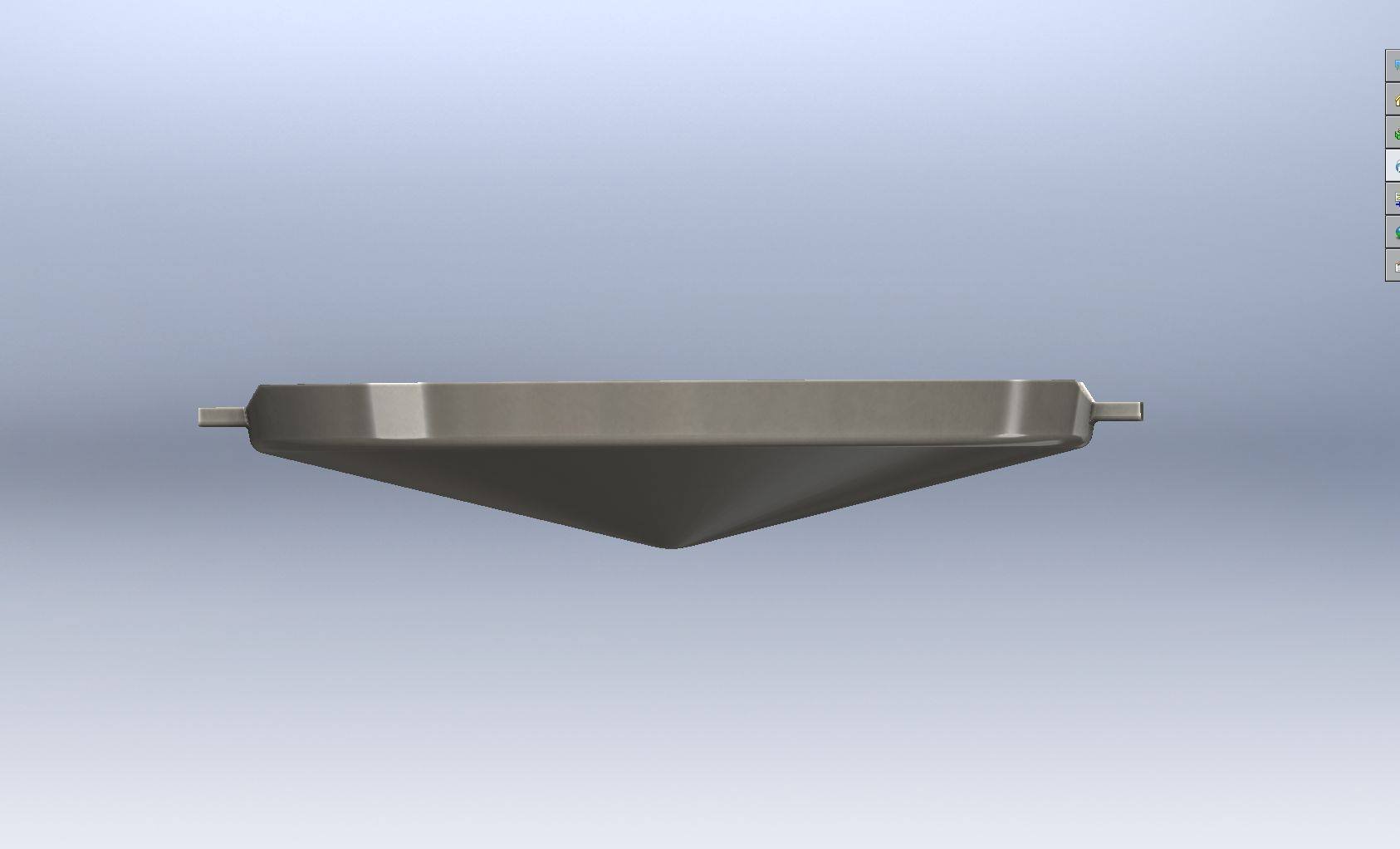

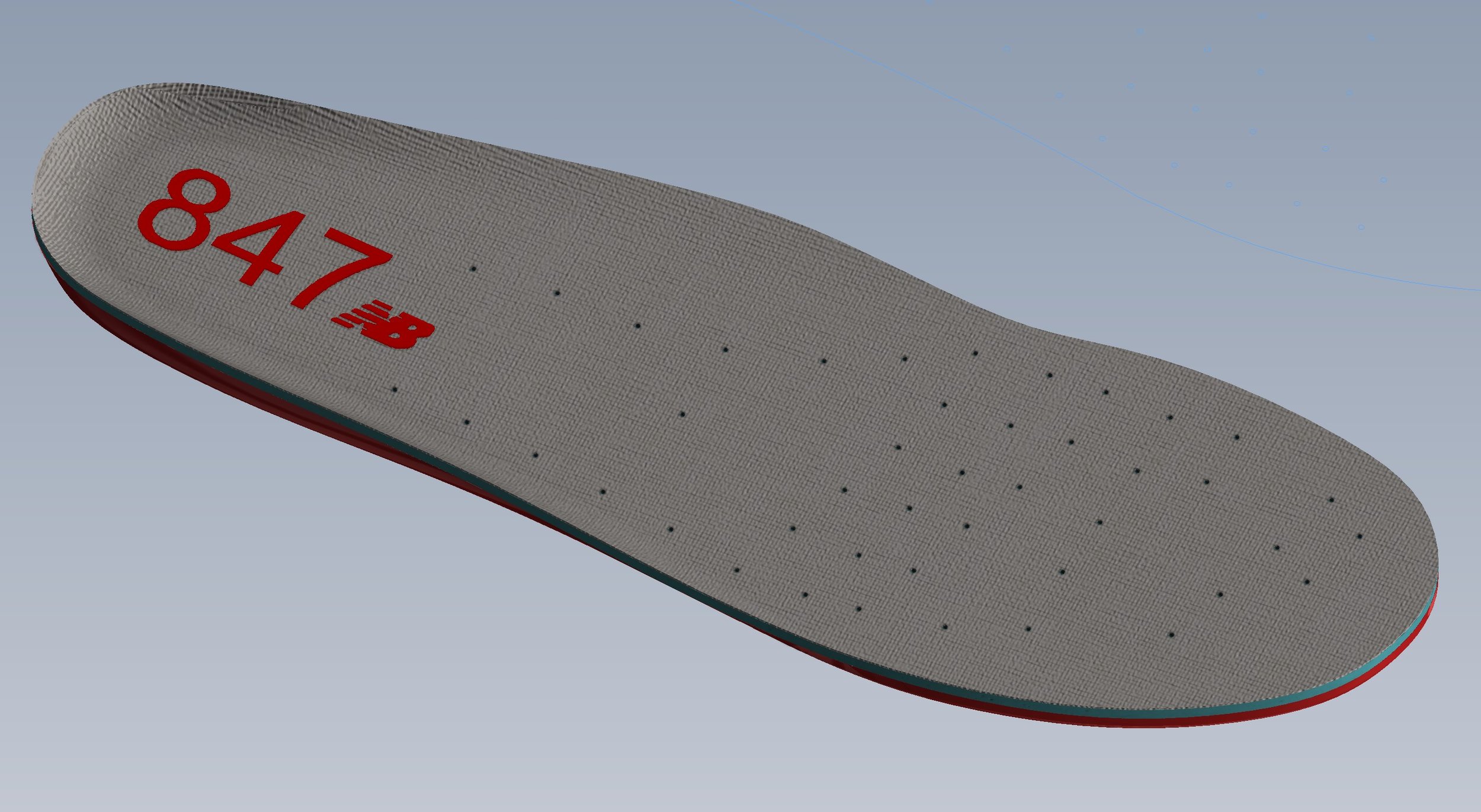

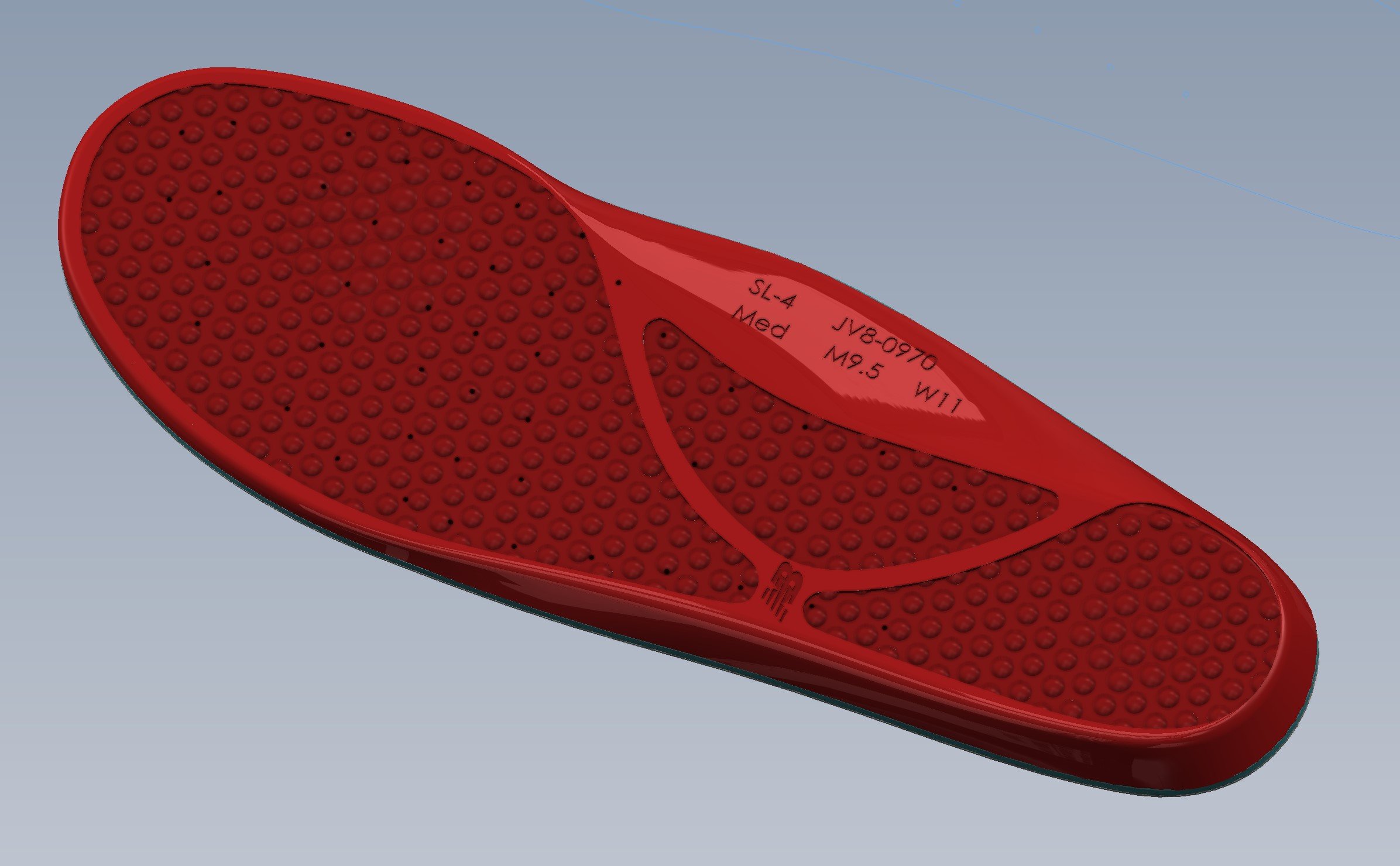

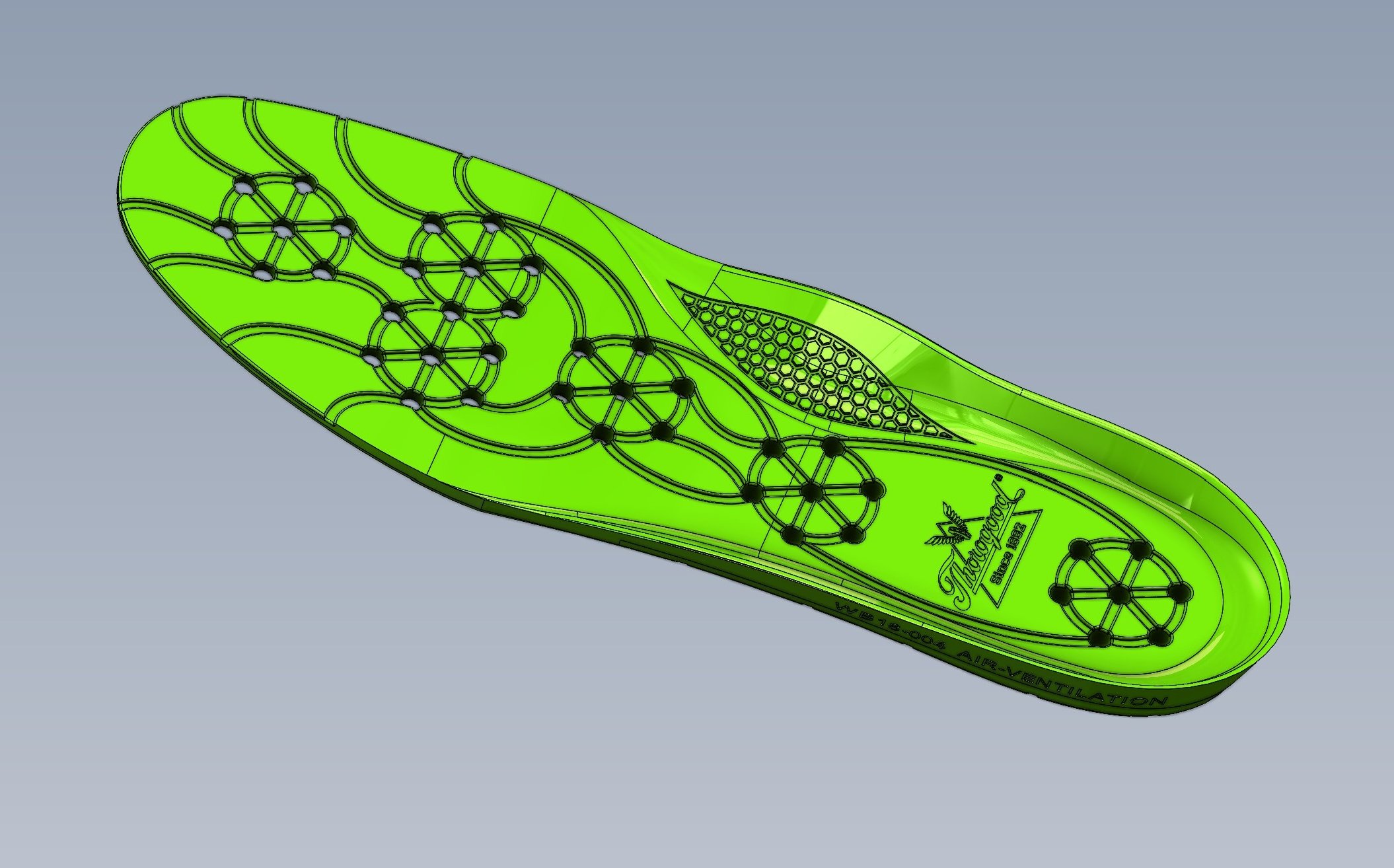

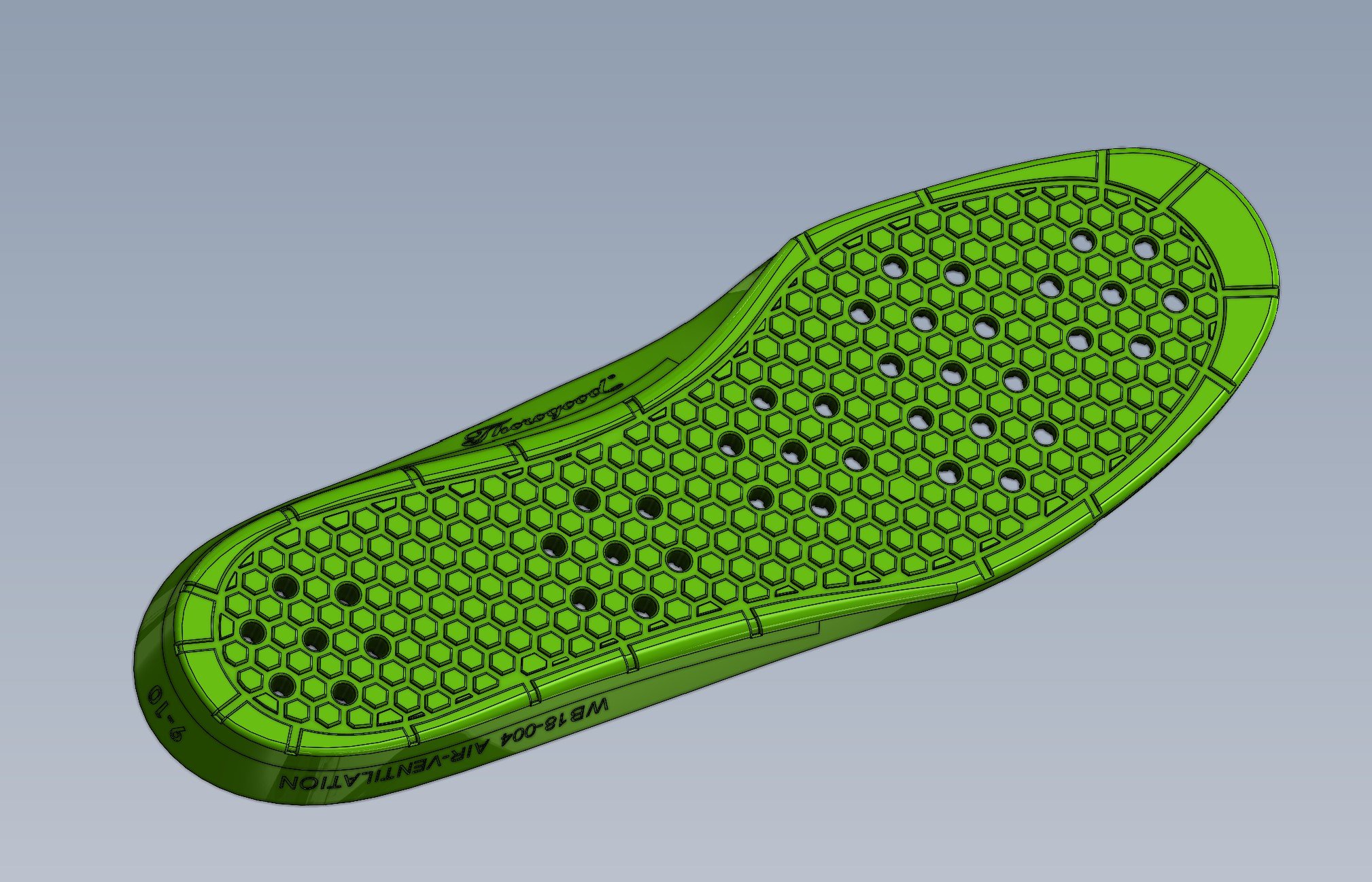

Foot Wear Inserts

and Orthotics

Broken Mantel Clock

This is a project that I worked on for a customer who tinkers with repairing old clocks. He wanted me to create a piece in CAD that he could either 3D print or use a pattern to cut it out of Walnut and sculpt by hand. I gave him both options to try. The fist pic is the clock that he is repairing. The second pic is what I used as a model. (It wasn’t an exact match but we improvised a little to match his clock.) The third pic is the image of his clock with my CAD model superimposed with it. The fourth pic is the CAD model with a Walnut finish. The Last pic is a 3D printed part made from a Wood like plastic that is a standard PLA plastic infused with wood fiber.

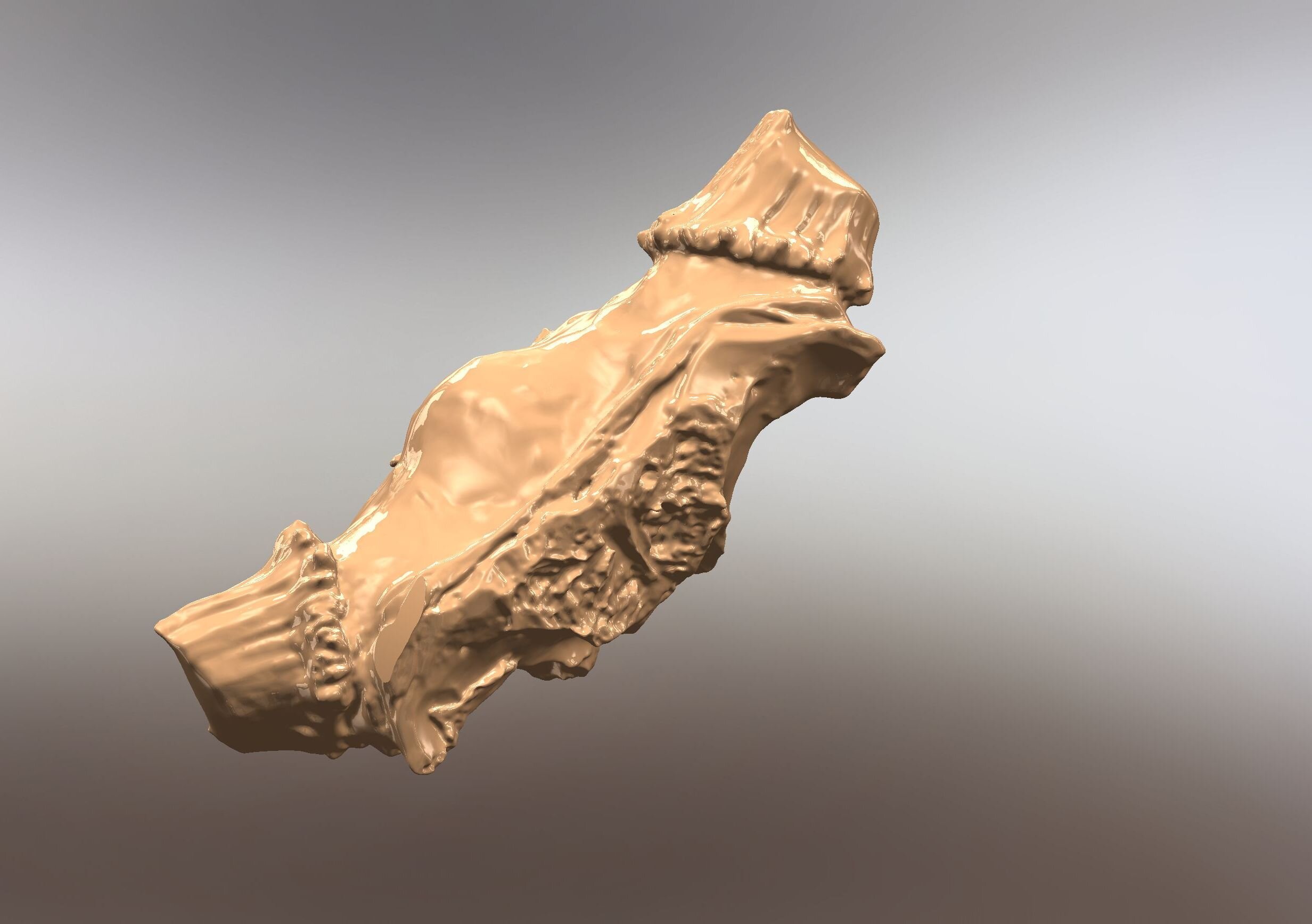

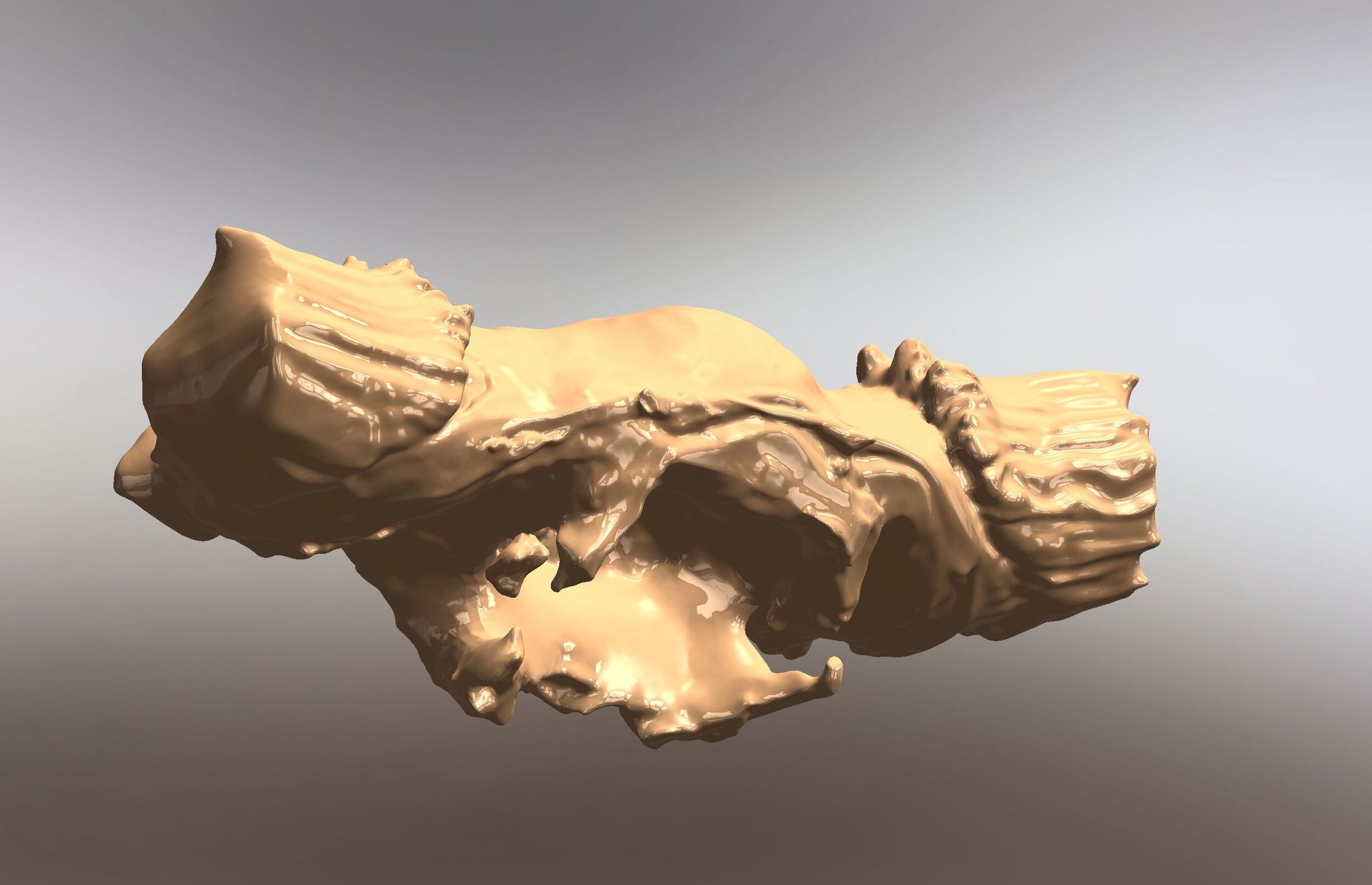

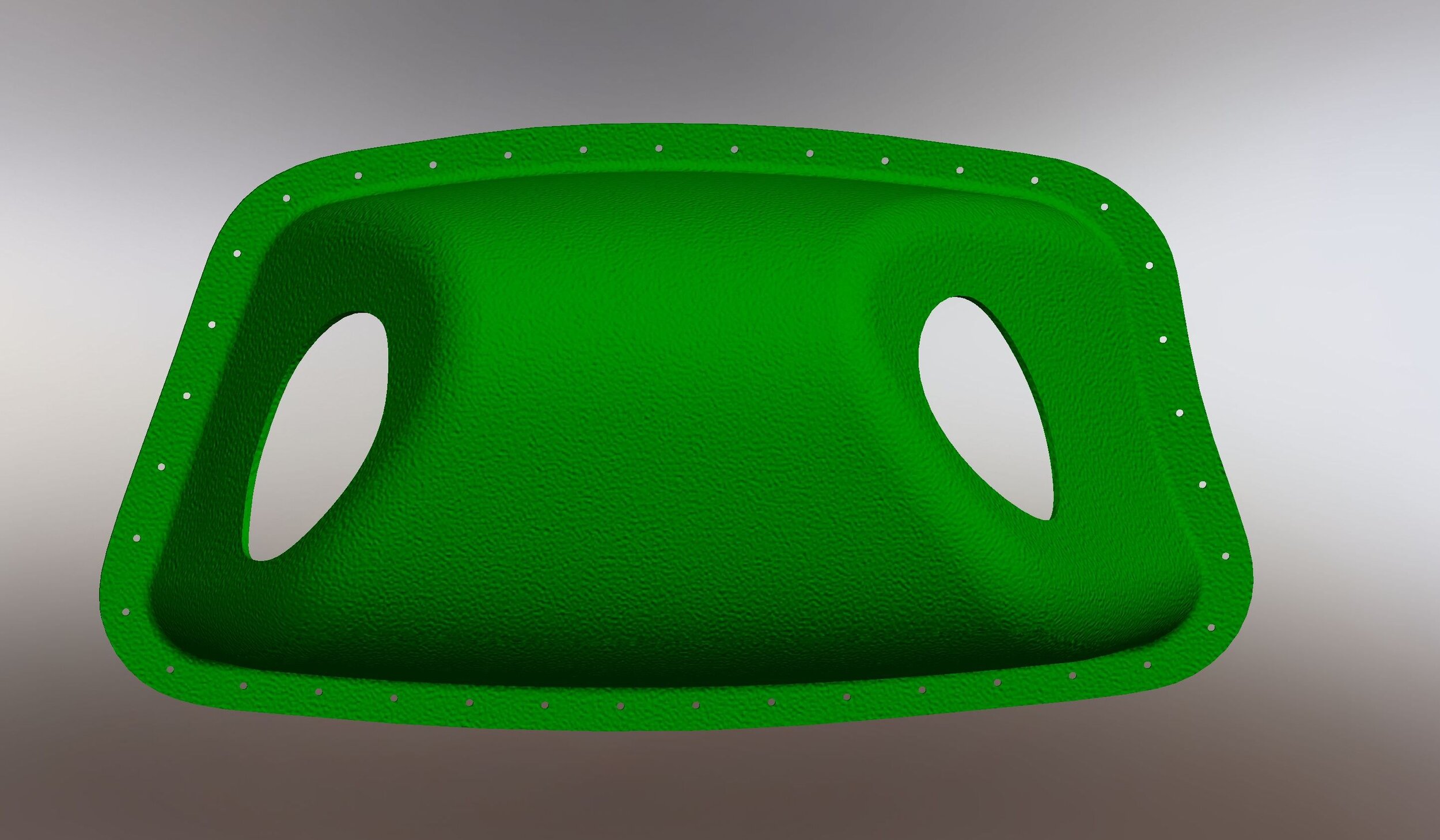

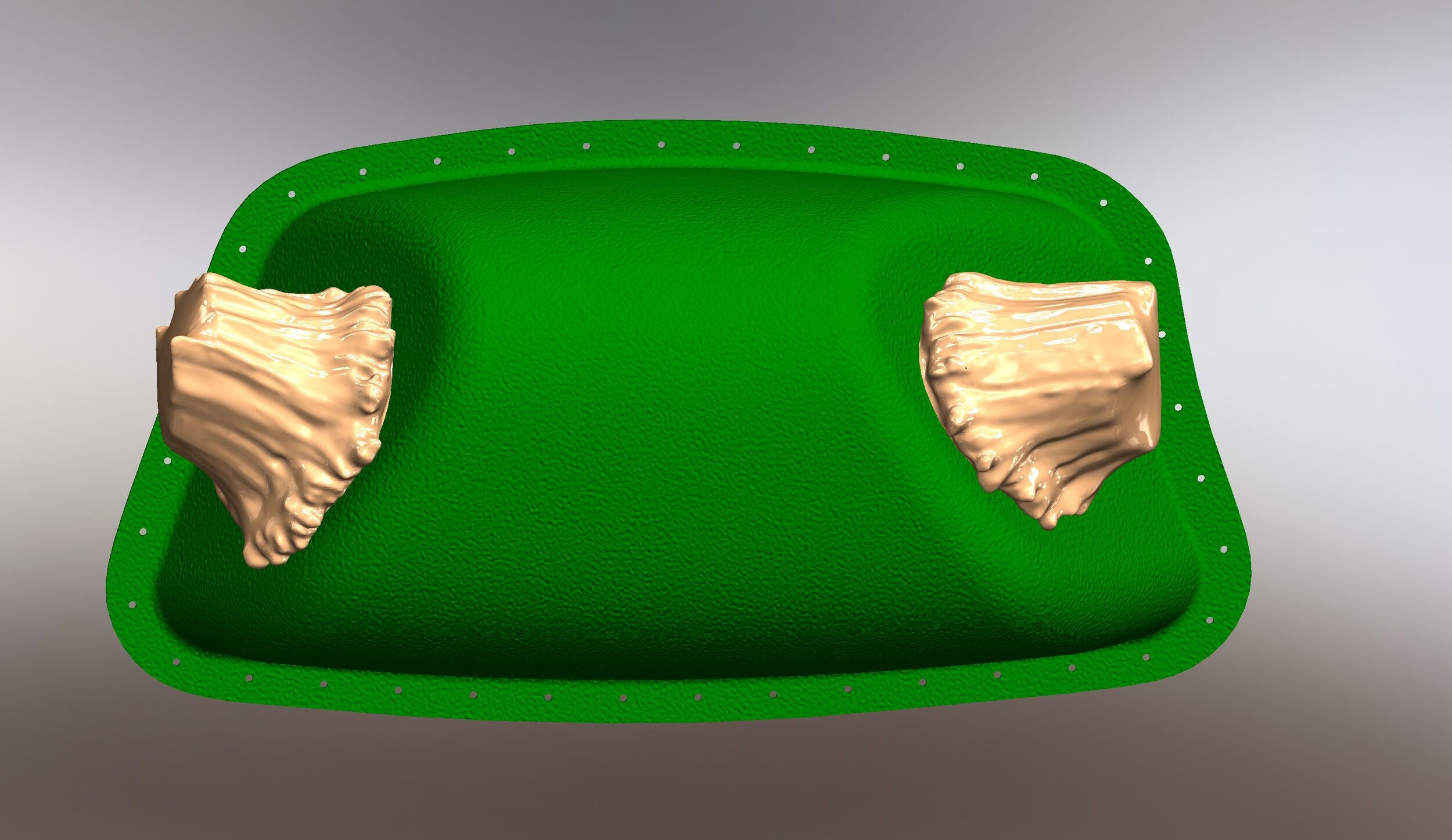

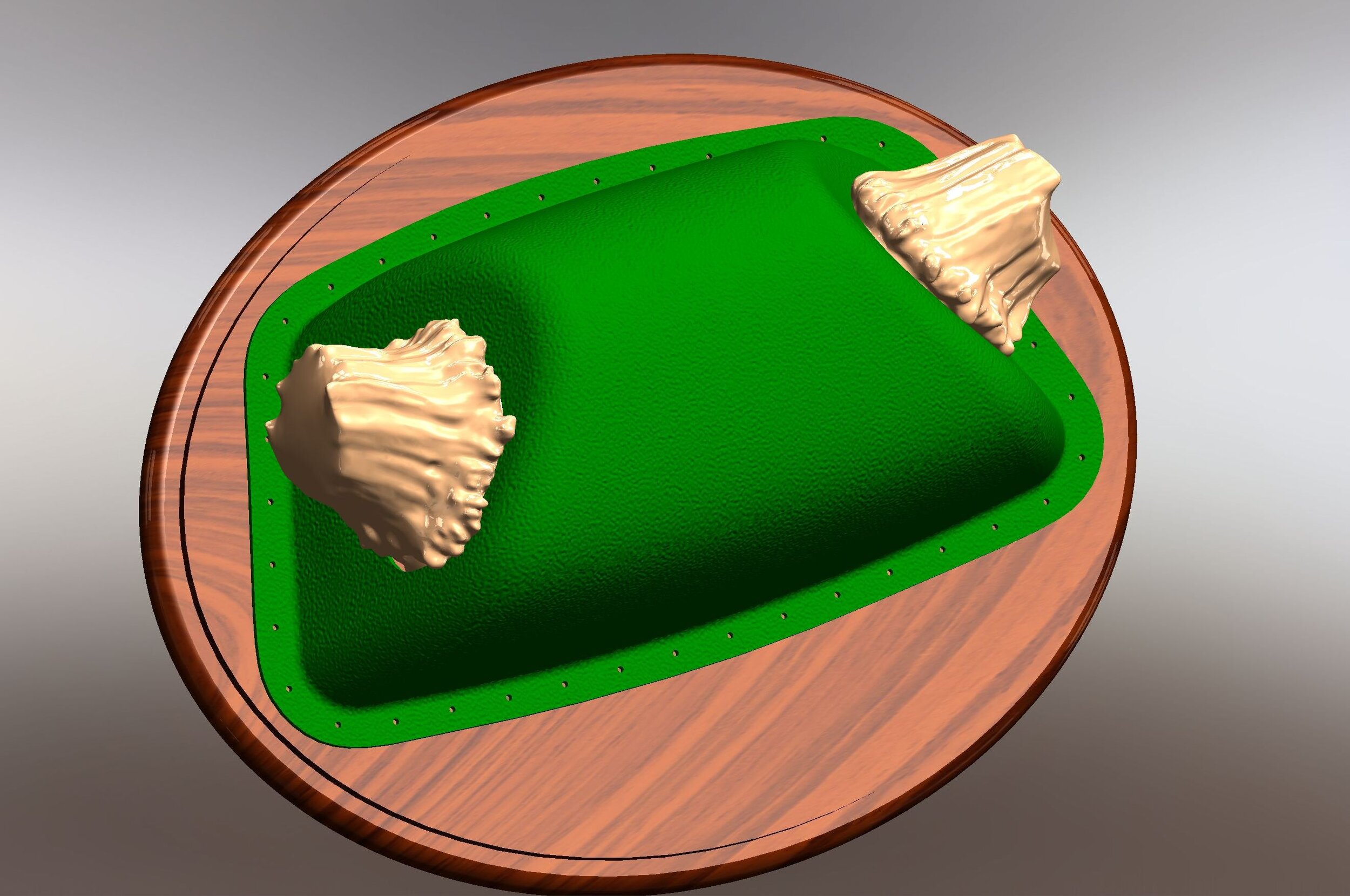

Moose Antler Skull Cover and Mount

This project was for myself. I was given the antlers from a friend and wanted to mount them on the wall. I decided to design and 3D print the skull cover. I choose to use a Green TPU for the cover because of the flexibility and it allowed me to slice the material under each antler to allow me to slip it over and tack it to the mounting board.

Custom Boot Insole

This is a custom insole that I worked on that was going into a pair of boots for a famous Country singer. The pic on the left is the original design. The middle pic is the final design and the last pic is the outsole with a guitar pick shaped clear rubber window to show the insole design.

Solidworks Animated video comparing two Shoe inserts

I made this for my Dad's 1967 Plymouth GTX dome light cover. He couldn't find a replacement for his so I modeled one and 3D printed it in white plastic.

Toe Pro

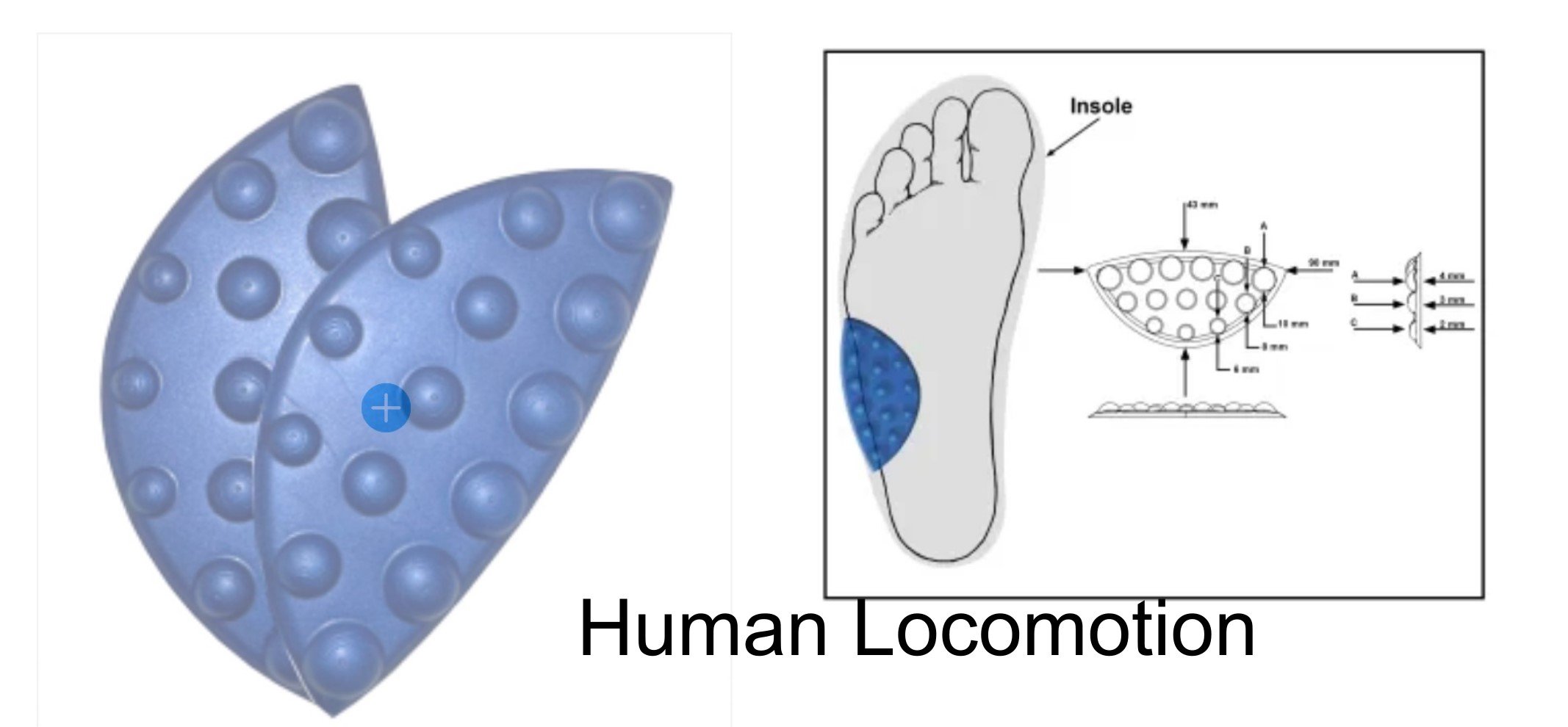

ToePro Foot/Ankle Exercise Platform

I built this in CAD for Human Locomotion as a way to help strengthen the muscles in the Legs and Back. All done with Surface modelling in Solidworks.

NoTork

This project was conceived by the mind of Adriano Rosa. This is an accessory for Archery enthusiast that allows for much more control over their bow.

I have created a couple of other products for him in the past for footwear applications. This was something totally different and fun to work with. I modeled each component for this. It includes package, strap and Finger rings. The images below are screen shots from the CAD software that I created this with.

I built this for a friend of mine that used to own a brewery. (It's closed down now) The resemblance of the foamy top to a Mullet is a total coincidence. I created it from the first image of the gallery which was a picture on his business card. I took a few liberties with the foam portion. The foam was sculpted in a product called FreeForm and then surfaced in GeoMagics and sent to SolidWorks where I built the rest of the geometry and merged the foam with the mug. I built this many years ago and Rapid Prototyped it with a Z-Corp machine.

This is the TBC Beer mug 3D printed on a Z-Corp single color machine.

Animated with Solidworks.

A little Solidworks Assembly and Animation that I did for the local Solidworks User Group.

Chris is the last of the Mohicans. I bet there are less than a handful with his experience left in the US. He is on top of his game in footwear engineering, 3D printing, mold design and last development.

Sal Maida – Maidas Custom Footwear